Sublimation printing is how you get those ridiculously vibrant, full-coverage designs that seem like they're part of the fabric itself—because they are. This isn't your standard screen printing where ink sits on top of the shirt. This is some next-level science.

It’s the secret sauce behind the most eye-popping apparel in the Print-On-Demand world, letting you create premium products that customers can't get enough of. If you want prints that never fade, crack, or peel, you're in the right place.

Ever see one of those incredible all-over-print hoodies or jerseys and wonder how they did it? That’s the magic of sublimation. It’s less about printing on fabric and more about infusing your design into it.

Here’s the breakdown: we print your design with special solid inks onto transfer paper. Then, using a heat press, we apply intense heat and pressure. This is where the transformation happens—the solid ink turns directly into a gas, skipping the liquid phase entirely.

This gas permeates the polyester fibers of the garment and, as it cools, permanently bonds with the material. The result? A breathtakingly sharp, vibrant print that has zero feel to it. It’s smooth, soft, and unbelievably durable.

For anyone trying to build an eCommerce brand, getting a handle on sublimation is like finding a cheat code. It's what separates the amateur-looking stuff from the professional, high-margin products that stand out.

Here’s why it’s so powerful for your business:

The market for this stuff is exploding. The global dye sublimation printing market hit USD 14.9 billion in 2024 and is on track to hit a staggering USD 28.0 billion by 2030. That kind of growth tells you everything you need to know. Smart entrepreneurs are building entire brands on this technology because it’s a proven business accelerator.

This guide is your complete roadmap. We're breaking down sublimation fabric printing from start to finish, showing you how to turn your ideas into a profitable business that gets people excited and builds a loyal fanbase.

If you’re just getting your feet wet, our guide on what is Print on Demand is the perfect place to start building your foundation. From there, this guide will give you everything you need to turn your vision into a killer online store. The opportunity is right here, right now.

The magic of sublimation all boils down to one critical choice: the material you print on.

Think of it like this: a master painter wouldn't try to create a masterpiece on a wet paper towel. They need the right canvas to hold the paint and make the colors pop. In sublimation, your fabric is that canvas, and picking the right one is everything.

The whole process hinges on a simple chemical reaction. Sublimation ink is specially designed to bond with polymers. This is why polyester and items with a special polymer coating are the undisputed champs for this printing method. When you apply heat, the pores of the polyester fibers literally open up, letting the vaporized ink fuse permanently inside them.

This molecular bond is what creates those stunningly vibrant prints that feel like they're part of the fabric itself—because they actually are.

If you're chasing after those jaw-droppingly sharp and intensely colorful prints, 100% polyester is the gold standard. It's non-negotiable. This fabric allows the maximum amount of ink to bond, resulting in true photo-quality images that demand attention.

It’s the go-to for products where the visuals are everything:

There's a reason the industry has doubled down on this method. Sublimation inks dominate the digital textile printing world, holding a massive market share of over 63% in 2024. This isn't just a trend; it's a proven formula for professional-grade products that survive countless washes, making it perfect for the Print-On-Demand activewear and custom fashion taking over ecommerce.

While 100% polyester gives you that super-vibrant look, don't sleep on polyester blends (like a 65/35 poly-cotton mix). These open up a totally different creative lane.

Since the ink only bonds to the polyester, printing on a blend gives you a softer, more muted "vintage" or "heathered" effect. This aesthetic is huge in certain niches and can give your brand a distinct, retro vibe. It's an awesome way to diversify your catalog. The trick is knowing how to design for this specific outcome, which we cover in our guide on how to design for Print on Demand.

Key Takeaway: The higher the polyester count, the brighter the print. The lower the count, the more faded and vintage your final product will look.

Now, let's talk about what to avoid. Trying to sublimate on 100% cotton is a complete waste of time and money. The ink has zero polymer fibers to grab onto. The design will look washed out from the get-go and will pretty much disappear after the first wash. Just don't do it.

This "polymer-first" rule isn't just for fabric. The world of sublimation goes way beyond apparel into cool products like coffee mugs, phone cases, and keychains. Each of these items is prepped with a special polymer coating that acts just like polyester, allowing your designs to infuse permanently onto their surfaces. This is how you can expand your store with tons of new product lines, all using the same incredible process.

To make it even clearer, here’s a quick-glance table to help you decide which material is right for your project.

| Fabric Type | Sublimation Compatibility | Expected Print Result | Best For |

|---|---|---|---|

| 100% Polyester | Excellent | Maximum vibrancy, photo-quality, sharp details, permanent. | Sportswear, banners, photo gifts, all-over-print fashion. |

| Polyester Blends | Good | Muted, soft "vintage" or "heathered" look. | Retro-style t-shirts, casual wear, hoodies with a unique aesthetic. |

| 100% Cotton | Not Recommended | Extremely faded, washes out almost completely after one cycle. | Nothing. Avoid this for sublimation printing at all costs. |

| Poly-Coated Hard Goods | Excellent | Sharp, vibrant, and glossy finish on a hard surface. | Mugs, phone cases, coasters, keychains, and other promotional items. |

This guide should be your starting point. Always remember the core principle: for sublimation to work its magic, it needs polymer to bond with. Whether that’s in the threads of a shirt or a coating on a mug, it's the secret ingredient to incredible prints.

Alright, let's get you set up. Building your sublimation station is like assembling the perfect workshop—you need the right tools for the job. Getting this part right is what separates the Print-On-Demand stores that take off from the ones that never quite get off the ground. This isn't about buying the most expensive gear; it's about picking reliable, workhorse equipment that lets you create killer products your customers will rave about.

Your whole operation really boils down to three core pieces working together. First up is a dedicated sublimation printer, the engine of your setup. Next, you've got specialized sublimation inks, which have that unique bit of chemistry that lets them turn from a solid to a gas under heat. Finally, high-quality sublimation paper is the carrier, moving your design from the printer to its final destination.

Get these three things right, and you're on your way to creating crisp, vibrant transfers.

While the printer puts your design on paper, the heat press is where the magic really happens. This machine delivers the two crucial ingredients for sublimation: intense heat and even, consistent pressure. It's the final step that transforms that dull-looking print into a brilliant, permanent design embedded right into the fabric's fibers.

Heat presses come in a few different flavors, and each one is suited for different products.

Choosing your press is a massive decision. It's a foundational piece of your workshop that directly impacts the quality and consistency of every single item you ship out.

Great equipment is only half the battle. To make sure every single press comes out perfectly, you’ll need a few other critical supplies to round out your toolkit. These small items make a huge difference in getting professional-grade results and avoiding costly mistakes.

Think of them as cheap insurance for your production process:

Don't sleep on these supplies. Mastering their use is the secret to cutting down on waste and making sure every product that leaves your shop meets the highest quality standards.

The market for this equipment is absolutely booming, which just shows the massive opportunity in the POD space. In fact, the global sublimation printing equipment market is projected to hit USD 4.1 billion by 2032. For entrepreneurs like us, this growth signals a stable, expanding industry with low setup costs that can easily support 30-50% profit margins—the exact model our Apparel Cloning system is built on. Sublimation’s cost-effectiveness makes it perfect for finding and dominating untapped niches. You can dig into more of these industry trends in this market research on sublimation equipment.

When you're looking at the core of your setup—the printer—a detailed guide can help you sort through your options. An Epson Printer for Sublimation Printing is a popular and solid choice for a lot of new businesses. By putting together the right toolkit from day one, you’re not just buying equipment; you’re building a system for long-term success.

Alright, this is where the magic happens—the moment your creative vision becomes a real, tangible product you can sell. You've got your gear ready, so let's walk through the entire sublimation process from start to finish. Don't think of this as a rigid set of rules, but more like a repeatable system you can perfect. A production line for creating incredible products for your brand, time and time again.

We're going to break down the whole workflow into simple, actionable steps. Nailing this framework will build your confidence and help you create that consistent system, which is really the foundation of any successful Print-On-Demand business. The goal is to make production feel like second nature so you can focus on what really matters: growing your brand.

Every killer product starts with a great design. For sublimation, that means a high-resolution digital file, typically at 300 DPI (dots per inch). Trust me, you don't want to skip this. A high-res file is what ensures your final print is sharp and professional—not a blurry, pixelated mess on a t-shirt.

You also have to pay close attention to color. Your computer screen shows colors in RGB (Red, Green, Blue), but your printer thinks in CMYK (Cyan, Magenta, Yellow, Black). Using the right color profile is the difference between the vibrant colors on your screen and a disappointing, washed-out final product.

Honestly, this design stage is where most new entrepreneurs get stuck. Making one great design is tough; trying to create hundreds to test in the market can feel impossible. This is the exact reason we built AvatarIQ. It’s an AI tool designed for Print-On-Demand sellers, letting you generate thousands of unique, print-ready designs and slick mockups in just minutes. It completely removes that creative roadblock, giving you an unfair advantage to test more ideas and find winning products faster than anyone else.

Once your design is good to go, it's time to print it onto that special sublimation paper using your dedicated sublimation printer. Before you hit "print," though, you've got to dial in your printer settings to get the best possible transfer.

There are a few key things to double-check every single time:

When the paper comes out of the printer, the design might look a little dull or faded. Don't panic—that's totally normal. The real, brilliant colors are just waiting to be activated by the heat.

This is the main event. It’s where the science of sublimation fabric printing comes to life, turning that piece of paper into a permanent design fused into the garment. Getting this right comes down to three critical variables: time, temperature, and pressure.

The exact settings will vary a bit based on your fabric and heat press, but a solid starting point for most 100% polyester apparel is around 400°F (204°C) for 60 seconds with medium pressure.

Pro-Tip: Always pre-press your garment for 5-10 seconds before you put the transfer on. This simple step gets rid of any moisture and wrinkles, giving you a perfectly smooth surface for a flawless print.

Carefully lay your printed transfer paper face down on the garment. Grab a few small pieces of heat-resistant tape and use them to secure the paper firmly in place. This is a crucial little step that prevents the paper from shifting during the press, which is the number one cause of "ghosting" or blurry edges on a print.

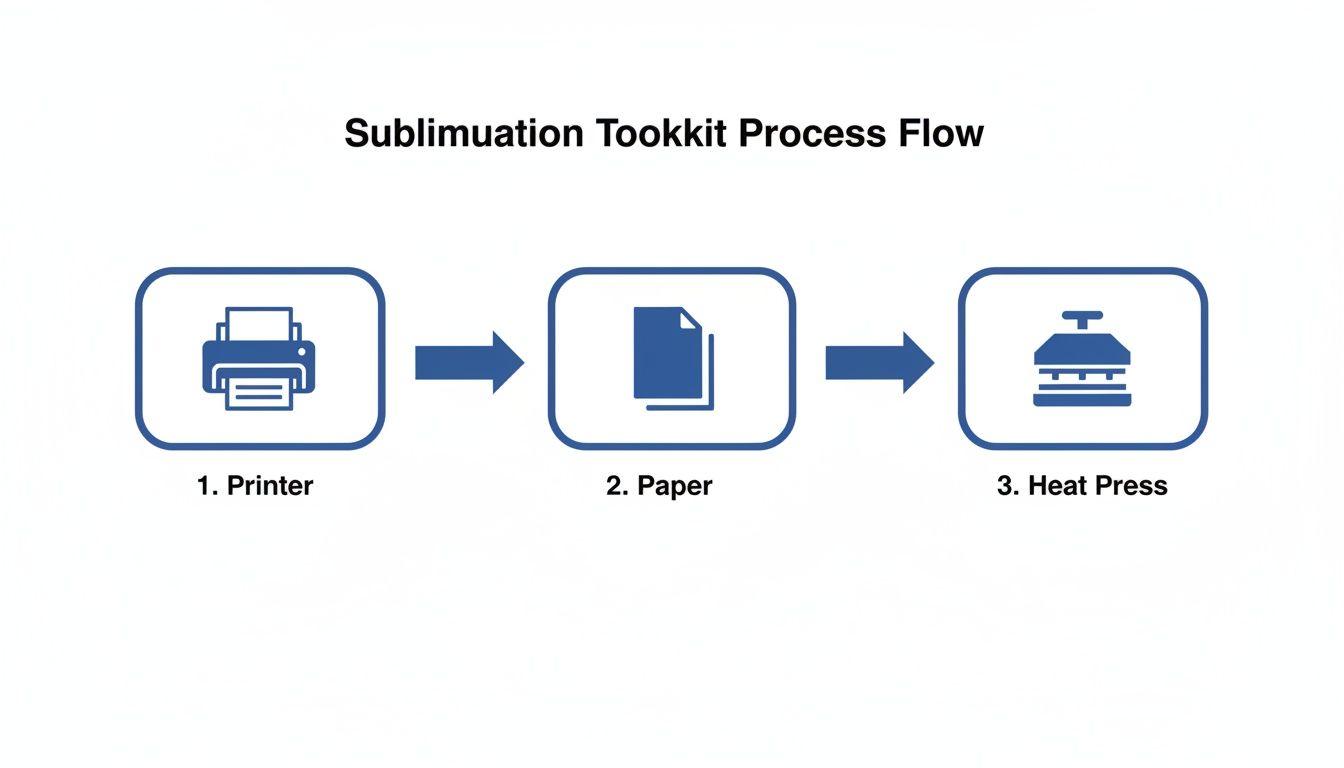

This flowchart lays out the core equipment flow of the whole process.

As you can see, each piece of equipment—the printer, the paper, and the heat press—plays its part in a specific order to get the job done.

Once that timer beeps, open the press carefully. For the absolute best results, you'll want to remove the transfer paper in one smooth, quick motion while the garment is still hot. This is what we call a "hot peel," and it helps lock in the sharpest possible image.

Let the garment cool down for a minute, then take a look at your work. You should see a stunning, vibrant design that has zero feel to it. It’s not sitting on top of the fabric; it is the fabric. That ink is now a permanent part of the garment, ready to survive countless washes without ever cracking, peeling, or fading.

This is the kind of quality that builds an incredible brand and keeps customers coming back. You’ve just created a premium product, and you have a process you can repeat and scale to build the business you've been dreaming of.

Even with the best gear and a dialed-in process, you’re eventually going to run into a print that just doesn't look right. Don't sweat it—this is a normal part of the learning curve, and knowing how to diagnose these little hiccups is what separates the pros from the folks who give up.

Think of this as your go-to field guide for fixing the most common sublimation headaches. Getting this right isn't just about saving one bad print. It’s about building a system that cuts down on waste, saves money, and protects your reputation for putting out top-notch products. This is how you build a real brand.

One of the most frustrating things to see is a blurry shadow or a faint double image on your final product. This is called ghosting, and it almost always means the sublimation paper shifted while you were pressing or peeling it away. Even a millimeter of movement is enough to wreck an otherwise perfect print.

The fix is dead simple but absolutely essential. You have to use heat-resistant tape to lock your transfer paper to the garment. Make sure to tape down at least two opposite sides so it can't slide around. This tiny step is your insurance policy for a crisp, sharp transfer every single time.

If you’re new to sublimation, your first look at the printed transfer paper can be a little alarming. The colors often look dull, faded, or just plain wrong. Take a deep breath—this is completely normal. In fact, it's a sign that everything is working exactly as it should.

Sublimation inks are designed to be heat-activated. On paper, they’re just sitting there in a solid, dormant state. It’s only when they hit the high temperatures of the heat press—usually around 400°F (204°C)—that they vaporize into a gas and reveal their true, vibrant colors as they bond with the polyester fibers. Trust the process. The real color pop happens at the very end.

Key Insight: Don't judge the final print by how it looks on the paper. The magic happens under heat and pressure, turning those dull inks into brilliant, permanent designs.

Ever pull a shirt off the press and see faded patches next to perfectly vibrant areas? That splotchy look is almost always a dead giveaway for uneven pressure from your heat press. If the press isn't clamping down with the same force everywhere, some spots just won't get enough contact for a full ink transfer.

First, double-check your heat press’s pressure settings—you’re typically looking for a medium-to-firm setting. If that doesn't fix it, your platen might be warped or the foam pad could be worn out. A great trick is to slide a Teflon pillow or a foam pad inside the garment. This helps distribute the pressure more evenly, especially around tricky areas like seams, collars, and zippers.

Sometimes you might notice tiny, starburst-shaped ink spots bleeding out from the edges of your design. These little blemishes, often called blowouts or gassing out, are caused by moisture. When moisture trapped in the fabric or paper instantly turns to steam in the heat press, it can literally push the ink gas outward.

The solution is a quick but crucial step in your workflow: pre-press your garment. Before you even think about laying down your transfer, press the blank item for 5-10 seconds. This zaps any trapped humidity, creating a perfectly dry canvas for a clean, flawless sublimation transfer.

When a print goes wrong, it's easy to get frustrated. But nearly every issue has a logical cause and a straightforward fix. Here’s a quick diagnostic table to help you identify what's going on and get back to making amazing products.

| Problem | Potential Cause | Solution |

|---|---|---|

| Ghosting / Double Image | Transfer paper shifted during pressing or removal. | Secure the paper to the substrate with heat-resistant tape on at least two sides. |

| Dull / Faded Colors | The print looks fine on paper but weak on the fabric. Usually an incorrect time, temperature, or pressure setting. | Check your substrate's recommended settings. Increase time or temperature slightly. Ensure you're using medium-firm pressure. |

| Colors Look Wrong | Your ICC profile is incorrect or not being used by your design software. | Ensure the correct ICC profile for your specific ink/paper combo is installed and applied in your printing preferences. |

| Uneven / Splotchy Print | Uneven pressure from the heat press. | Check your press's pressure settings. Use a Teflon pillow or foam pad to distribute pressure evenly, especially over seams. |

| Tiny Ink Specks ("Blowout") | Moisture in the fabric or transfer paper turned to steam during pressing. | Always pre-press your garment for 5-10 seconds to remove any residual moisture before applying the transfer. |

| White Creases or Lines | The fabric was folded or creased during pressing, preventing ink from reaching those areas. | Smooth the garment completely on the press before closing. Be mindful of seams and collars. |

Think of this table as your first line of defense. By understanding these common culprits, you can quickly get back on track and minimize wasted materials.

Okay, you've nailed the technical side. You’ve got the gear, you understand the process, and you can troubleshoot with the best of them. Now it's time for a mental shift. Sublimation fabric printing isn't just a way to make cool stuff; it's the engine for building a real, scalable eCommerce brand. And Print-On-Demand (POD) is the high-octane fuel that makes it go.

This is where things get really exciting. The magic of the POD model is that you can list and sell hundreds of unique products without ever touching a single piece of inventory yourself. You focus on creating the designs and marketing your brand. When a customer orders, a third-party partner handles the printing, packing, and shipping. This incredible model removes the risk and the massive upfront investment of buying stock, letting you pour all your energy into growth.

When you pair the premium, vibrant quality of sublimation with the lean efficiency of POD, you create a business that’s built for speed and profit. This is how you go from a creative hobby to a full-time income and genuine financial freedom.

Let's be honest, the hardest part of eCommerce isn't making the product—it's figuring out what to sell. Burning through your time and money on designs that nobody wants is the quickest path to frustration. That’s exactly why we developed our Apparel Cloning system. It’s a battle-tested method for finding proven, winning product ideas and then replicating that success with your own unique twist in fresh, untapped niches.

Instead of guessing what might work, you use data to see what’s already selling. Then you just apply your own creativity. This approach dramatically increases your odds of launching a bestseller right from day one.

So, you've identified a winning product idea. Now what? The next big bottleneck is creating enough high-quality designs to test different niches and see what your audience actually connects with. Trying to do this all by hand is a painfully slow and frustrating process that absolutely kills momentum.

This is the exact problem AvatarIQ was built to solve. It's our proprietary AI tool, designed from the ground up for ambitious POD sellers like you. With AvatarIQ, you can generate thousands of unique, high-resolution, print-ready designs in a matter of minutes, not months. It gives you the power to test ideas at a scale that was simply impossible before, giving you a massive edge. You find winning designs faster, launch products quicker, and scale your brand with total confidence.

The modern eCommerce opportunity is all about building efficient systems. By using frameworks like Apparel Cloning and tools like AvatarIQ, you automate the tedious parts of the business so you can pour your energy into marketing and scaling.

The road to building a successful brand is more accessible than it's ever been, and sublimation is your ticket in. But having the right production knowledge is only part of the puzzle. For those ready to take their venture to the next level, understanding the bigger picture of launching a successful fashion business can provide a crucial strategic roadmap.

This entire business model thrives on a seamless connection to a powerful eCommerce platform. To get your store up and running with this system, check out our detailed guide on how to add Print on Demand to Shopify. The chance to build a brand that can truly provide for you and your family is right here, right now. All you have to do is take that first step.

Jumping into any new business always brings up a few questions. To tackle those last-minute uncertainties head-on and get you started with confidence, here are the most common things people ask when they're new to sublimation fabric printing.

I wish it were that simple! The short answer is no—a standard inkjet printer from your local office supply store just won’t cut it without some serious internal surgery.

Sublimation relies on a special kind of ink that has a unique chemical reaction to heat. To get those jaw-dropping results, you need a printer built specifically for sublimation. The only exception is certain Epson models that have a reputation for being easy to convert for sublimation use.

If you’re asking this, congratulations—you're on the right track! This is one of those classic "trust the process" moments in sublimation.

Sublimation inks are designed to be dull and muted on the transfer paper. Their true, vibrant colors only come alive when they hit the right temperature and pressure in your heat press. At that point, the ink turns into a gas and permanently bonds with the polyester fibers. Don't panic if it looks washed out on paper; the magic happens in the final step.

This is a core concept of sublimation fabric printing. The design goes from a dull, lifeless print on paper to a brilliant, permanent graphic on the fabric, but only after it gets the right amount of heat and pressure.

This is a mistake you only make once. Sublimation ink is chemically engineered to bond with polymers, which is exactly what polyester is made of. Cotton, on the other hand, is a natural fiber with nothing for the ink to grab onto.

If you press a design onto a 100% cotton shirt, it will look incredibly faded right from the start. Even worse, it will almost completely wash out the first time you put it in the laundry. For results that last and look professional, you have to stick with fabrics that have a high polyester content.

While you can get started with basic design software, you’ll discover that scaling your business requires a more powerful solution.

For any Print-On-Demand entrepreneur who wants to grow, a tool like AvatarIQ is a total game-changer. It's an AI-powered platform built to help you generate thousands of unique, high-resolution designs and create professional-looking mockups in a fraction of the time. It completely removes the creative bottleneck, freeing you up to focus on what really grows the business: marketing, testing new ideas, and making sales.

At Skup, we're here to give you the tools, training, and support to build the eCommerce business you've always wanted. Stop guessing and start building with proven systems. Explore our training programs at Skup.net.